Bare Panel Ceiling

PRODUCT STRUCTURAL PERFORMANCE STRICTLY

AS PER CISCA STANDARDS 2007

Concentrated : Load 363 kgs (800 lbf) accroding to

(Point Load) ISCA A/F, Section concentrated loads.

Uniformaily Distributed : 1658 kg/m2 UDL Pneumatic Bag TEST

Load (UDL) as per CISCA testing Standards 2007

3100 kgm2 UDL using 305 x 305 mm

source intermationally) tested for a

maximum deflection at 1.02 mm.

Ultimate Concentrated : 1089 kgs (2400 lbf) according to CISCA

A/F Section II Ultimate Loading.

Roiling Loads : 180 Kgs (400 lbf) according to CISCA

A/F Section III Rolling Loading.

Fire Rating : Class O & Class 1,

Contforming to ASTEME 84 1998

(Flammability) & ASTM E 136 (Combustibility)

Pedestal Axial Load Test : 22 KN according to CISCA A/F, Section V,

Pedestal Axial Load Test.

Pedestal Over Turning : 113 N x Meters Moment Test.

PANEL DESCRIPTION

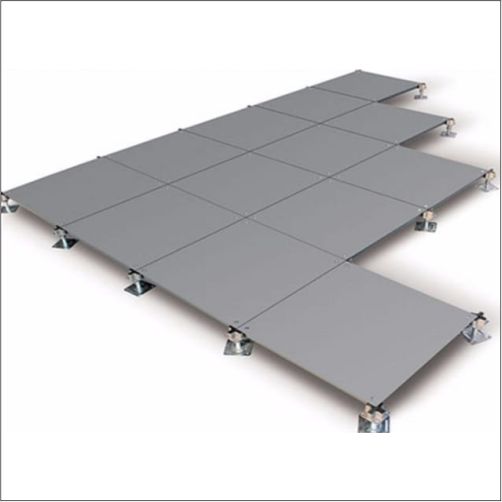

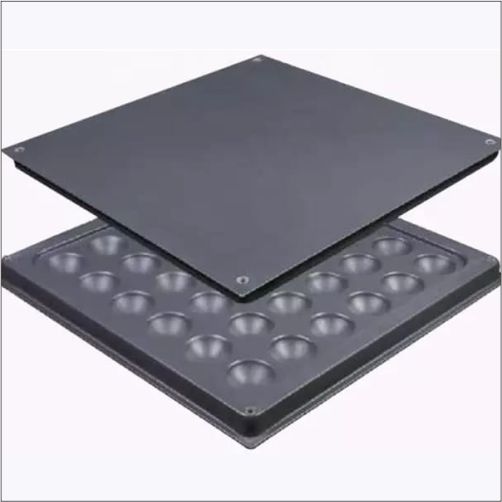

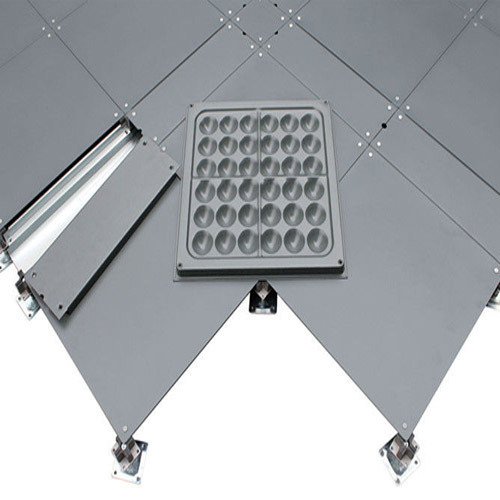

Laban 800 ibf access floor panels having dimensions of 600 x 600 mm shall be all stell welded construction with an enclosed bottom pan of 64 hemispherical cones. The top plain sheet is fuse welded to the bottom pan at 144 locations to form a hollow panel. The panel after required pre-treatment iscoated with 40-60 micron epoxy paint and heated to achieve maximum adhesion to the panel surface for resistance to corrosion. The inner empty care of the panelis injected with a lifht weight, non-combustible cementitious at high pressure to fill in all the crevices of the panel and ensure support of less than 96% of the top surface area of the panel. Panels shall be capable of withstanding 800 lbf point load tested as per CISCA testing procedures and conforming to Masterspeces.

SECTION 096900.

The panel has locator holes on all 4 corners, which are required to bolt the panel to substructure to form a rigid monolithic smooth levelled floor. Perimeter flanges of the bottom pan are provided with 16 gussets which also gets filled with light weight concreate to enhance structural strength and provide rigidity to perimeter flanges of the panel and hence to system too.

Adding gussets does not hinder the process of die cut trimming of the panels, which was also the case in our old generation modes.

SALIENT FEATURES OF DIE CUT TRIMMING

1. Allows additional 60 nos. of resistance welding sports to the panel totaling to 144 nos. of spot weld in the hollow panel, the

composite panel, the composite panel now is fat more rigid than the earlier version having only 64 sports.

2. Allows better corrosion protection to the edges of the panel in comparison to the the non diecut trimmed.

3. Allows consistent gap between adjacent installed pan between adjacent installed paneis enhancing sesthetics (no creases in the carpet, while also ensuring lesser air leakages when used for UFAD